General points:

The SCS / HIC / IHC is what every scooter requires to reduce (and prevent) any movement in your headset. It’s partly responsible for that nice “dong dong” sound you hear when your scooter hits the ground.

The SCS / HIC / IHC must be tight all the time, otherwise it could deform the headset.

Over the years, several standards have arisen and now you have the choice between four different systems. It can sometimes be a real brain-teaser to find out which system is compatible with which fork and bar...

Regardless of aesthetic differences, all SCS / HIC / IHCs do the same thing.

They compress the fork against the headset cap to keep the headset bearings in constant compression.

When tightening your SCS / HIC / IHC for the first time, it may loosen unusually regularly (one every few days,) and you’ll feel some movement in the headset, which is normal as each component takes a bit of time to ‘wear in.’

If the problem persists, inspect all the column components (i.e. as bars, fork, headset and SCS / HIC / IHC) to see if there is a cause.

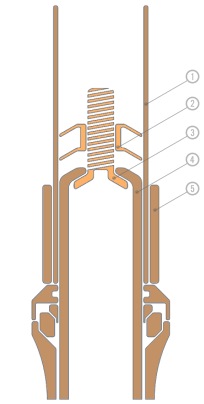

ICS:

1 : bar 31.8

2 : starnut

3 : compression screw

4 : fork

5 : clamp

Created by Andrew Broussard of PROTO (formally known as Scooter Resource Parts) in 2006.

The concept is rather simple – an internally-threaded starnut is installed inside the bars and an M6 bolt goes up through the fork-tube, screwing into the starnut.

This compresses the bars against the fork, thus tightening the headset.

The advantage is that the bar has direct contact with the fork, so there’s no need to tighten the clamp too hard.

Another thing is that because the only components are the starnut and bolt, it’s a very light system.

The original ICS SCS / HIC / IHCs used a long bolt (7”/18cm) and the head of the bolt remained inside the body of thefork,

allowing it to be tightened with the use of a small allen key.

However, these days companies are replacing them with short M6 ‘screws’ (virtually identical to the ones used in clamp.)

These rely on a ‘closed’ fork-tube with a small hole at the top, where the bolt’s thread can pass through to reach the starnut.

This was most likely done because M6 screws are much more common and also lighter.

In order to compensate for the short bolt, you will need a long allen key (~20cm) in order to reach the starnut to tighten it.

Ironically, these are about as uncommon as the M6 bolts!

Luckily, SCS / HIC / IHCs in need of this special tool will have one included, but try not to lose it!

The main disadvantage is that you need to remove the wheel every time you want to tighten it.

You also cannot remove the bars without fully loosening the compression.

As a simple pair of components, you rely heavily on the starnut maintaining its position.

With high-end bars, the steel is often heat treated, making it so dense that the starnut cannot grip onto the inside of the bar as easy and, as a result, slides down.

Aluminium is softer than there, so it’s a system that works better with aluminum bars.

It can also work great with a starnut that’s integrated inside the bar.

In 2011, Addict introduced the use of ‘ICS10.’ Instead of having a M6 thread, an M10 one is used, giving additional tightening strength (due to its bigger surface area.)

Unless you have a starnut installation kid, install the starnut into the bar will require a hammer.

Begin by lining the starnut up with the forktube.

To do so, we advise using a tube with a slightly smaller outer diameter than the bar’s inner diameter, covering the starnut and hitting the tube with the hammer.

The tube’s circular cross-section makes it easier to apply even pressure to the starnut and prevent it from ‘capsizing’ inside the forktube.

Try not to hammer it in too deep and or not need enough.

If it’s in too deep, the bolt/screw will be too short (essentially wasting a starnut.)

If it’s not in deep enough, the fork will touch the starnut and the system won’t work until it’s hammered in deeper.

The best thing to do is leave roughly 1 cm between end of the fork-tube and the starnut.

Always remember to loosen your clamp before tightening the SCS / HIC / IHC.

If you don’t, the pressure of the clamp on the fork will prevent it from moving, stopping it from reaching further inside to the bar.

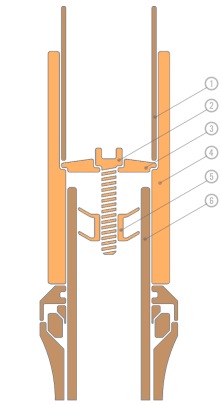

SCS:

1 : bar

2 : compression screw

3 : cap

4 : SCS

5 : starnut

6 : fork

Created by PROTO in 2008 (claiming it as ‘more efficient’ than their previous ICS,) this system is just as simple, but makes use of more components.

It’s a big clamp, separated into two compartments with different inner diameters – The upper which holds the bar and the lower which holds the fork.

Between the two compartments is a top cap, which sits on the edge created by the different diameters.

An M6 screw goes through the hole and directly into the fork, which holds a 1-1/8” starnut.

In order to use an SCS, you need to have a pair of bars without a slit.

If your bar already has a slit, just cut the bar above where it is.

The SCS raises the bar by 2” (~5cm,) so if you cut that length off the bar, the SCS will bring them bar to their original height when fitted.

The advantages of this system are that is very efficient, simple to set up, and often compatible with both standard and oversized bars (depending on your brand of SCS.)

Your opinion may be that it’s too big large (effecting the aesthetics of your scooter,) emphasised by its weight.

In addition, you’ll need to add ‘headset spacers’ under the SCS if your fork-tube is too long, in order for it to make contact with the headset cap.

Unlike ICS, you cannot tighten the compression without removing the bars, but there is no need to remove the front wheel.

Finally, it you cut a pair of bars down for use with an SCS, you will have to re-cut a slit if you decide to move back to ICS or maybe HIC, and as they go over the fork using these systems, they will be shorter to ride with.

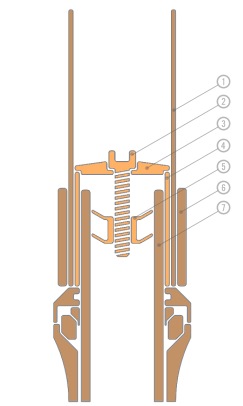

HIC:

1 : bar

2 : compression screw

3 : cap

4 : shim

5 : starnut

6 : clamp

7 : fork

Created by the Mosbrucker brothers of RADskoot.Co in 2007, this system requires Oversized bars which also have a larger inner diameter than the standard size (1-1/4”.)

This method of compression involves a shim, which goes over the fork.

A top cap is then placed on top of the shim, whilst a screw goes through the cap and into the starnut placed in the fork, thus compressing the components.

Once secure, the bars are able to slide over the shim and fork but be tightened against the shim with a double clamp.

Advantages: It’s a reasonably light system, though the oversized bars tend to be heavy.

They’re quite efficient and simple to use.

Disadvantages: Similar to SCS, you cannot tighten the compression without removing the bars first.

In addition, you need a very solid clamp and a pair of Oversized bars, which are pretty common in the US but not so much in Europe.

IHC: This system was created by Envy (formally known as Blunt) in 2011.

It’s essentially a variant of HIC, using a fork with a smaller external diameter.

This makes enough room for both a shim (also smaller in size) and standard size bars.

Advantage: No need to use an oversized bar. Another thing is the smaller fork-tube will be less weight than a normal one.

You get all the conveniences of HIC whilst being free to choose any standard size bars for use.

Disadvantages: Whilst ICS, SCS and HIC SCS / HIC / IHCs have been adopted by various scooter brands, Envy, Fasen and Slamm remain the only brands who manufacture IHC systems, leaving very little choice.

If you dislike the appearance of their IHC forks, this compression will be out of the question.

As it’s a smaller fork profile, you must also use a compression ring made specifically for this form of compression.

The fork should come with the ring included.

My Cart

0

- empty