General:

The front and rear axle are the components that fix the wheel to the deck and fork, respectively.

It’s also the component that is most prone to stress damage, as well as torsion due to the pegs.

That’s why it’s in your interest to have good quality axles so that they don’t risk being damaged whilst hitting big gaps.

All Scooter axles have an 8 mm diameter (the industry standard from day one,) to fit 608 bearings (the standard for kick scooters, rollerblades and skateboards.) Axles can be either internally of externally threaded. Internally-threaded axles are more light-weight, and generally made for use with 5 mm Allen keys. Externally-threaded axles are a bit heavier but are much stronger, and are generally made for sure with a spanner. Both types are compatible with pegs.

Brands use different types of steel to make pegs, but this is rarely specified as one of the product characteristics.

When installing your pegs, it’s very important to them on the opposite side to the threads, otherwise it will short their lifespan.

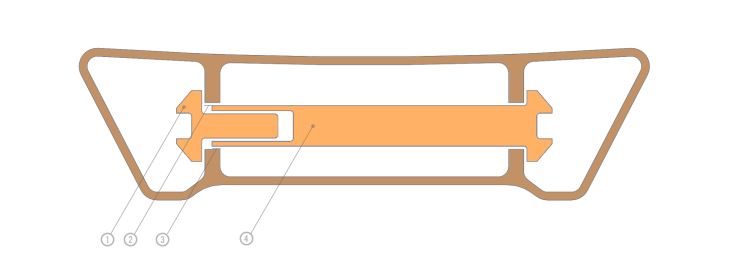

1 : axel screw

2 : compression space

3 : contact aera

4 : axel

Length :

Length is very important to have an efficient system, and the axles have to be in contact with the deck (or fork) on both ends. If it’s too short, but you can still put the screw inside the axle, but all the efforts will be on the junction between the two components, and it will break.

If it’s too long, just add spacers on the exterior of the deck/fork.

Titanium :

There are a few titanium axles on the market. Contrary to belief, titanium isn’t always more resistant than steel, though some special alloys have a resistance that isn’t far off. However, we would not recommend using pegs with titanium axles.

A big advantage with titanium axles is their flexibility, allowing them to absorb bigger shocks than steel. They’re also lighter by roughly 20 grams each.

My Cart

0

- empty