General points:

Currently, all bearing are the same: The ‘608’ standard.

Originally, these bearings were not made especially for skateboards or skates. They’re actually an industrial standard for all sorts of machines. It was only during the arrival of skateboards and roller skates which saw them adopted for freestyle use.

Contrary to belief, bearings are not the component most influential to the speed, that is the quality of the PU used on the wheels. Nonetheless, having good quality and well-maintained bearings can tip the scale

The ABEC Rating:

Many brands talk a lot about it, but the truth is that the ABEC doesn’t mean much in our world. Originally, it was an indication of tolerance quality used in the industry, to talk about machines running at hundreds of thousands of revolutions per minute (or RPM.) The index goes from 1 to 9.

In freestyle use, a bearing undergoes forces which this index does not take into consideration at all. For example, you could produce a wooden bearing with a rating of ABEC-9 with the best precision in the world, but it would immediately fall about the moment you step on your scooter.

Don’t rely on the ABEC rating to determine the quality of bearings. In our industry it’s nothing more than a commercial persuasion in order to sell more products.

All brands’ bearings are merely found in Chinese general bearing factories, except for Powell’s Bones, which are designed specifically for freestyle use.) Without any quality index, many are tried until they find one that fits. After that, they simply put their branding on it and sell it as their own.

Installation:

It’s almost an art to set up a bearing in a wheel, only emphasised by the fact machines can make small mistakes (0.1-0.2mm) in the bearings are being machined, often making it difficult install a bearing into a wheel. Before trying to install a bearing, it’s really important that you lubricate the bearing slow with oil or grease so that the bearing can slide in easier.

The proper method consists of aligning the bearing with the wheel’s bearing slot. Once achieved, use a fork axle and some spacers and tighten up everything to slowly press the bearings inside. But be careful – if a bearing goes askew, don’t force it in. Take it out and try again.

The ‘dirty’ method consists of hitting the bearing in. It’s possible but at great risk of damaging the internal components of the bearing. You must be careful to only hit the bearing’s outer race. Don’t hit the shield as that is required to protect the bearing from dirt and moisture when riding.

Remember, it’s not because a wheel is turning well in the air that it will be the same under your weight!

Maintenance:

It is possible to maintain your bearings by regularly removing the shield and cleaning them out. You can also find some specific products on the market which you can bath the bearing in to clean it up. This can also be achieved by using refrigerated alcohol.

Alternatively, you can replace the ball cage within the bearing all together. This can be done by removing the shield like before and replacing the cage that separates the balls. You can replace it with a cage with more or less balls depending on how responsive you want them to be. After stripping down the bearing, remember how to put it back together again!

If you change wheels, It’s better to use different bearings than other re-using the former bearings from an previous wheel. Removing the bearing from a wheel can often damage it, and the price of 2 bearings is not much compared to the price of a wheel.

Spacers:

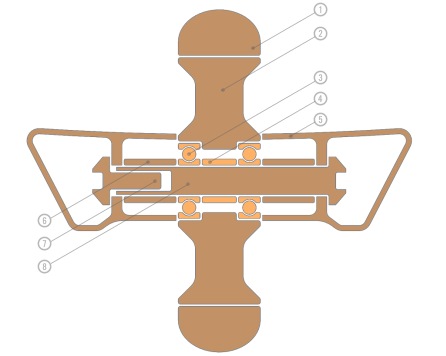

1 : wheel PU

2 : wheel core

3 : bearing

4 : bearing spacer

5 : deck

6 : deck spacer

7 : screw

8 : axel

The spacer between the bearings is essential to ensure the bearing works well. Without it, the bearing will undergo compression from both sides as soon as you tighten the axle. They’re not made to endure that kind of force, so avoid it to maintain the life of the bearings.

Shields:

The Shields are the flat rings that lie between the inner and outer race and protect the bearing from dirt and moisture. They can be found on either side or just on one side. Usually one is enough, but it needs to be facing outwards when fitted in the wheel.

You can find both steel shields (608ZZ) and plastic shields (608DD.) If they experience a shock severe enough, a steel shield can deform and make contact with the balls/cage, preventing their movement. Because of this, we recommend bearings with plastic shields (which are softer and more elastic.)

Ceramic bearings:

Ceramic bearings really are the best product to choose. As it is not self-explanatory – only the balls are made of ceramic. Ceramic has roughly 3 times the resistance of steel. Ceramic cannot rust, and does not distend under heat, like steel balls do.

But these are only for the committed riders, as ceramic bearings are much more expensive, but if money is no object, then we definitely recommend them.

My Cart

0

- empty