General:

A clamp applies pressure in order to keep components together. You’ll most likely be familiar with the ‘collar clamp,’ which is necessary to keep the bars perpendicular to the wheel (so that you maintain a sense of direction,) as well as keeping the bars and the fork together, either through direct contact with each other or separately within the clamp. Clamps can also be used in Lock-on grips or Quick-release handlebars, but these are no longer common.

Some people think that when they get unwanted movement in their bars, they simply need to tighten the clamp harder - that is totally useless. A clamp has never been made for that, even if you tighten as hard as you can, movement will always come back. That’s why a SCS / HIC / IHC is essential.

So to use your clamp effectively, tighten it but not too hard. For a double clamp, first tighten the lower screw, then the upper one, then the lower one some more. The idea is to alternate between the pressure areas, as not to damage the clamp.

Number of screws:

The number of bolts in these clamps typically ranges from 1 screw and 4, with even 6 screws clamps being available.

But think about it logically – Anything beyond two screws is essentially useless as they tend to reach above the slit and put pressure on part of steer-tube that will not distribute any of this pressure onto the fork. It’s unnecessary weight.

If the bars and forks are well maintained with a slit of reasonable size, a mere single-bolt clamp can be enough to keep everything ‘in line’. A double clamp is further means of ensuring that everything stays in place (Bear in mind that the lower screw is always more efficient that the upper one because it’s nearer to the slit).

Weight:

The clamp’s weight is insignificant, especially as it’s at the front of the scooter, so it will not affect the deck’s rotation efficiency.

Sizes:

As there are two standards in bar diameters, there are two sizes of clamps. These are known as ‘standard’ and ‘oversized.’ Standard measures at 1-1/4” (approximately 38.1mm for those who use the metric system) and oversized at 34.9mm. Oversized clamps can be adapted for compatibility with standard-sized bars by using a shim that will fill the space between the clamp and the bar.

Steel inserts:

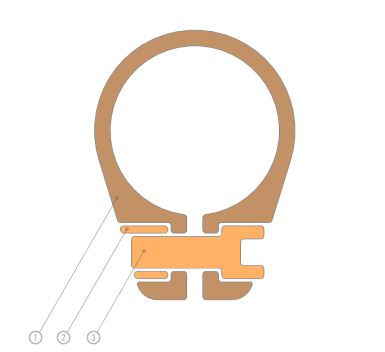

1 : clamp

2 : screw

3 : steel insert

As steel against aluminum is never a good thing, it’s possible that if you tighten the steel screw too hard, it might strip the thread, which is in aluminum.

Some clamps have steel insets to prevent this from happening, allowing you to tighten further, but the screw can still snap if you tighten too hard, so be careful.

My Cart

0

- empty